As previously discussed on my post covering several dead D-series NEC drives, NEC had quite the history in the hard drive industry. NEC’s 3.5″ designs would enter in the early 90’s, like competitors at the time, the D3756 being a drive from the early days of their original designs. After many years of experience developing MFM-based units, NEC clearly knew how to make a good drive.

This particular drive has failed quite nastily, unfortunately. As usual, that means we can take a look inside! Be sure to wear your ear protection for this one…

Drive Attributes

-------------------------------------

NEC D3756

-------------------------------------

Capacity 105MB

Mfc Date 1993-02

Format 3.5"

Interface PATA

Platters 2

Heads 4

Cache 32KB

RPM 3456

CHS 1251/4/41 (native)

625/8/41 (translated)

Origin Philippines (TEII)

-------------------------------------

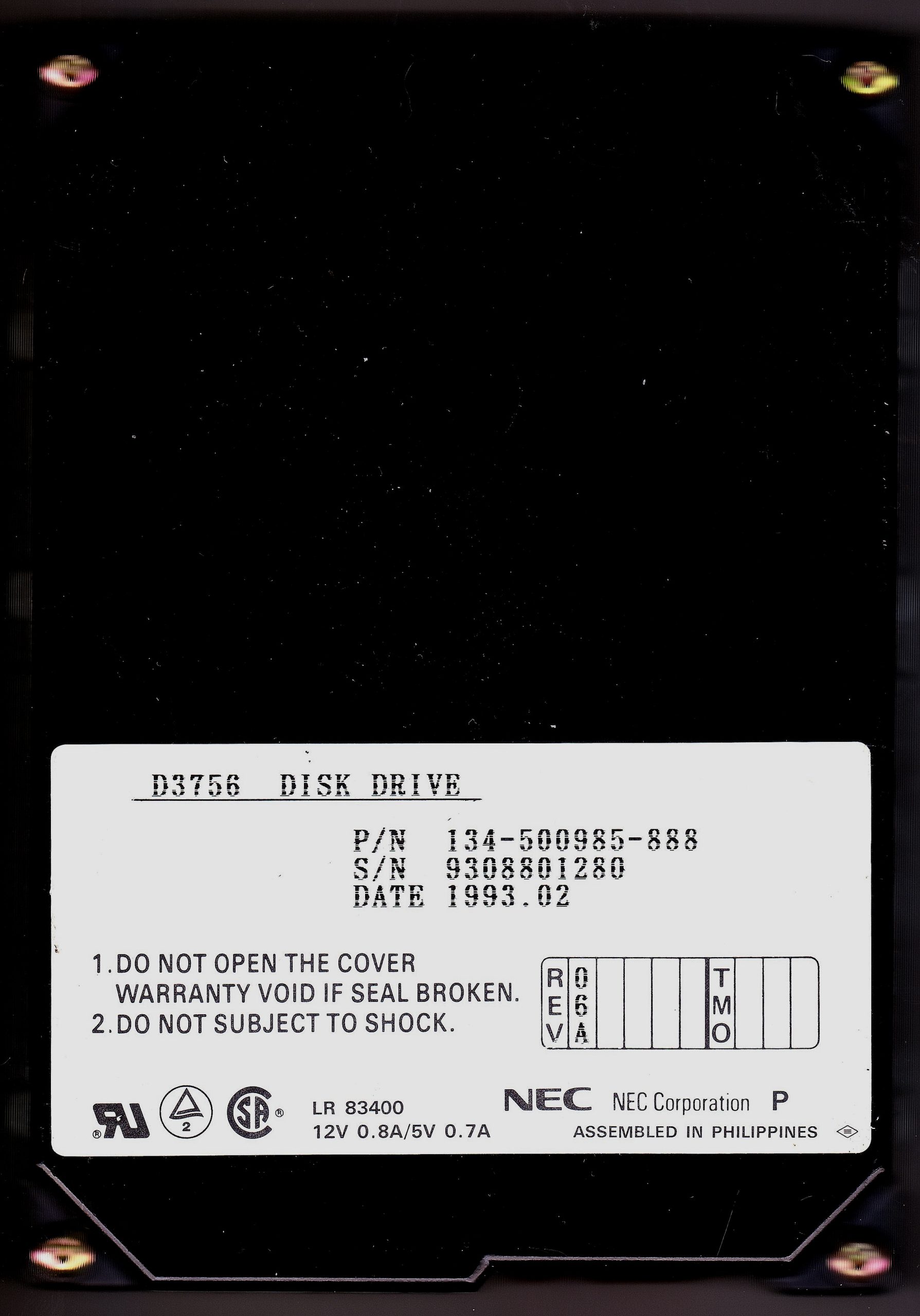

Suffice to say, this is quite the good looking drive. A clean black-painted exterior, with very little to speak about.

This HDA design served as the basis of future models in NEC’s line-up, such as with the D3711. These have 2 platters, equating to 52.5MB per-platter, with 26.25MB per-surface. The spindle RPM is rather odd, coming in at 3456 RPM according to NEC’s datasheet. Neat.

Streaky printing aside, the label design on these is simple and reasonable well laid-out. It does, however, lack useful information such as drive capacity. These drives were manufactured in both Japan and the Philippines, this one hailing from the latter. NEC would later open its own factory in the Philippines, but this one comes from an entirely different plant, being subcontracted to Tsukiden Electronics Industries, Inc. (TEII).

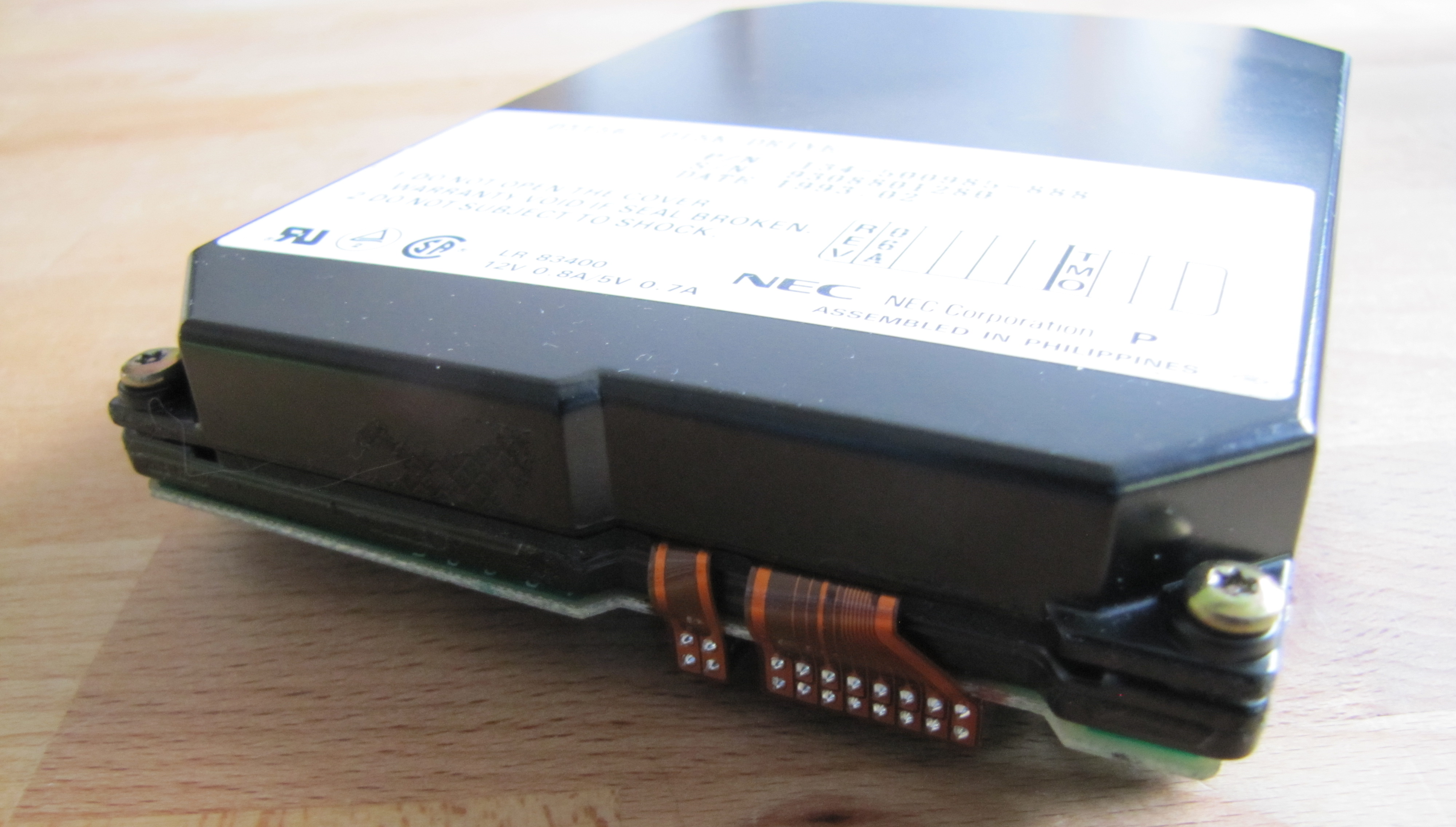

An unassuming rear-side. The connectors are well-molded, as one would expect at this point in time.

It’s worth noting, the tape seal surrounding this drive had already been removed at the time of this post. Obviously, the drive didn’t arrive in my possession like that.

Here we’re faced with the head-stack interconnection ribbon cables. That’s all to see!

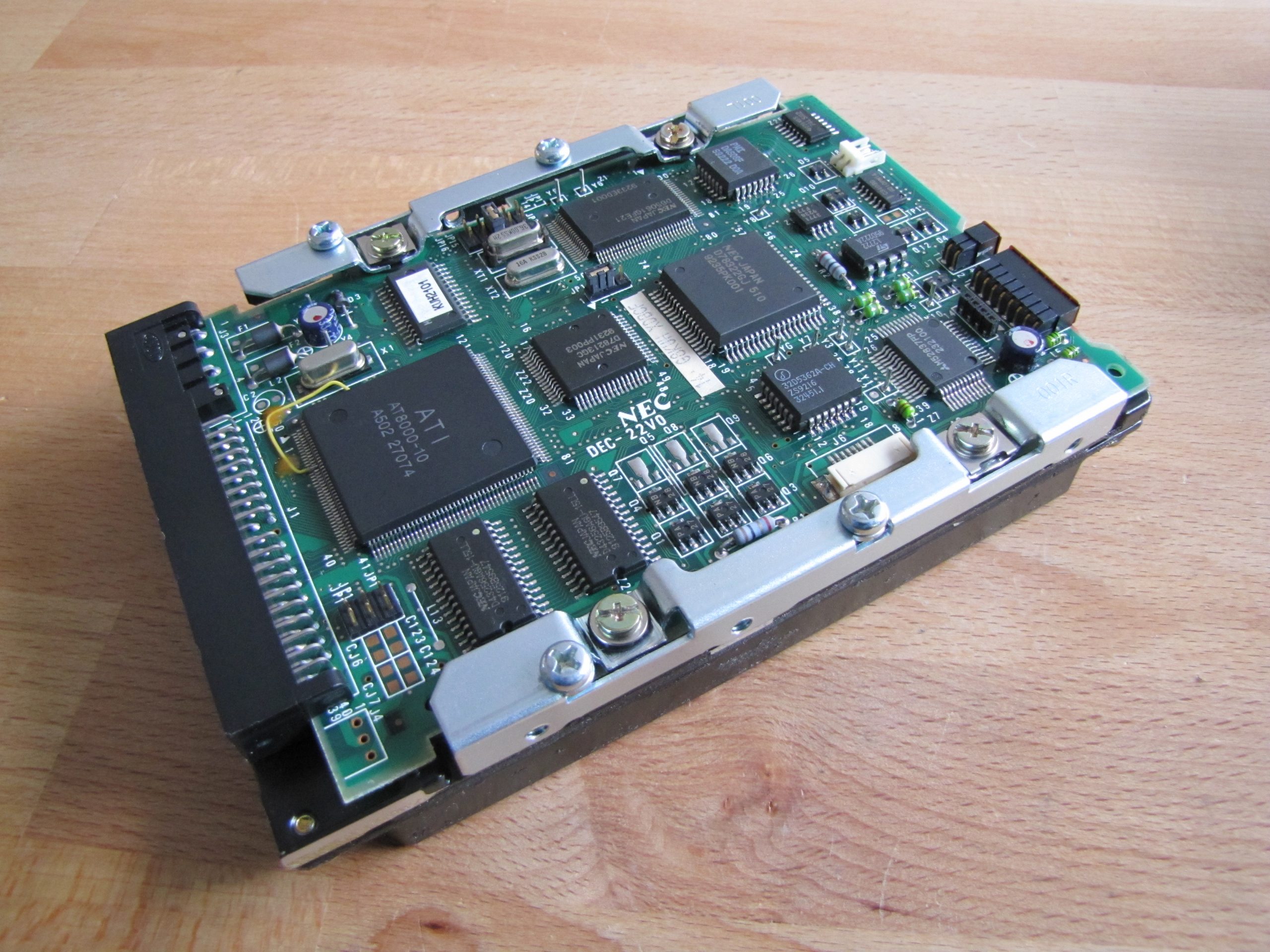

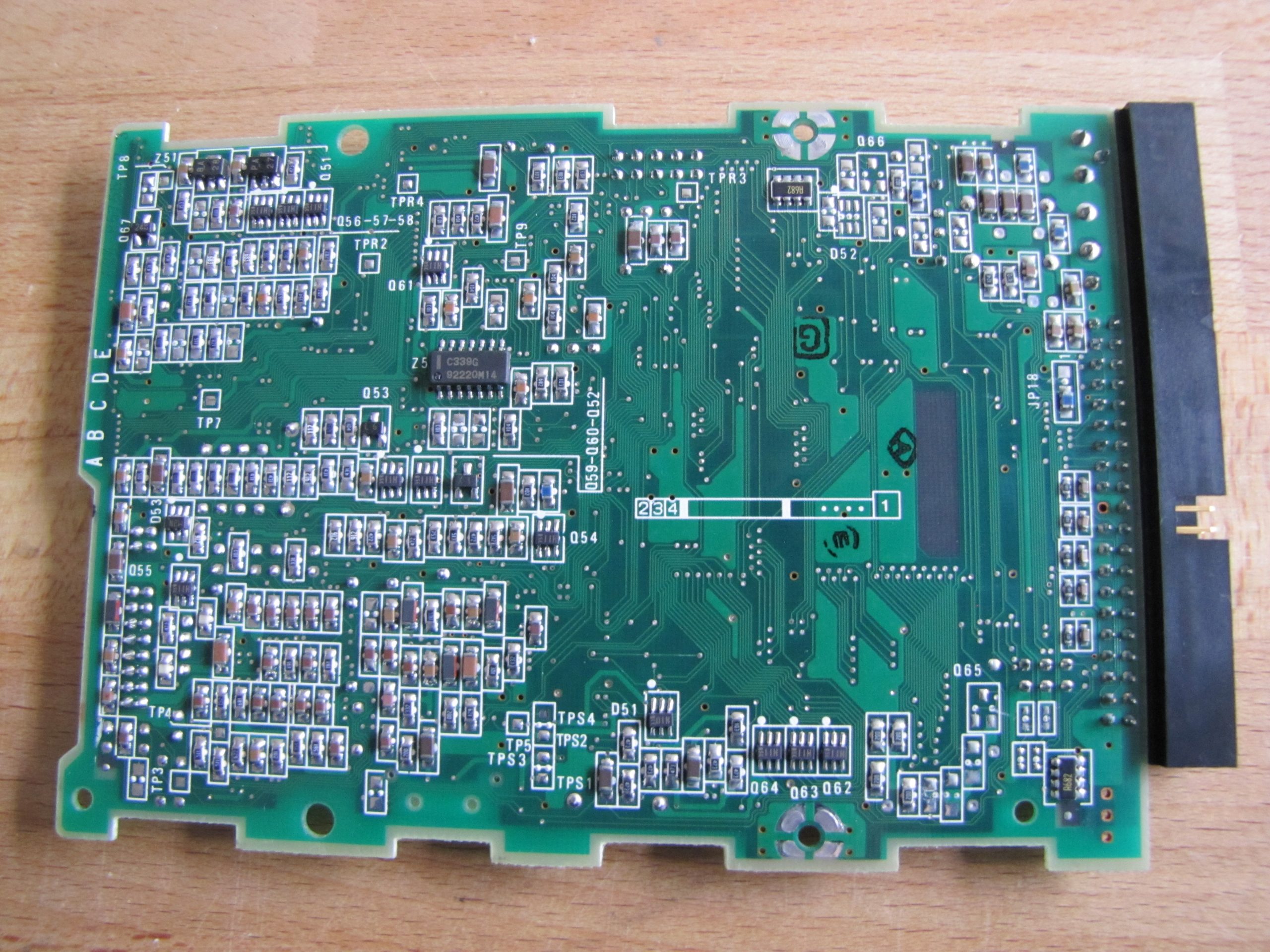

The overall PCB design on these is quite a bit different to future NEC designs, alongside bearing their old logo design. This can sometimes be seen on this particular model’s label too, if the drive is old enough.

Unlike this drives overall assembly, the PCB was manufactured in Japan.

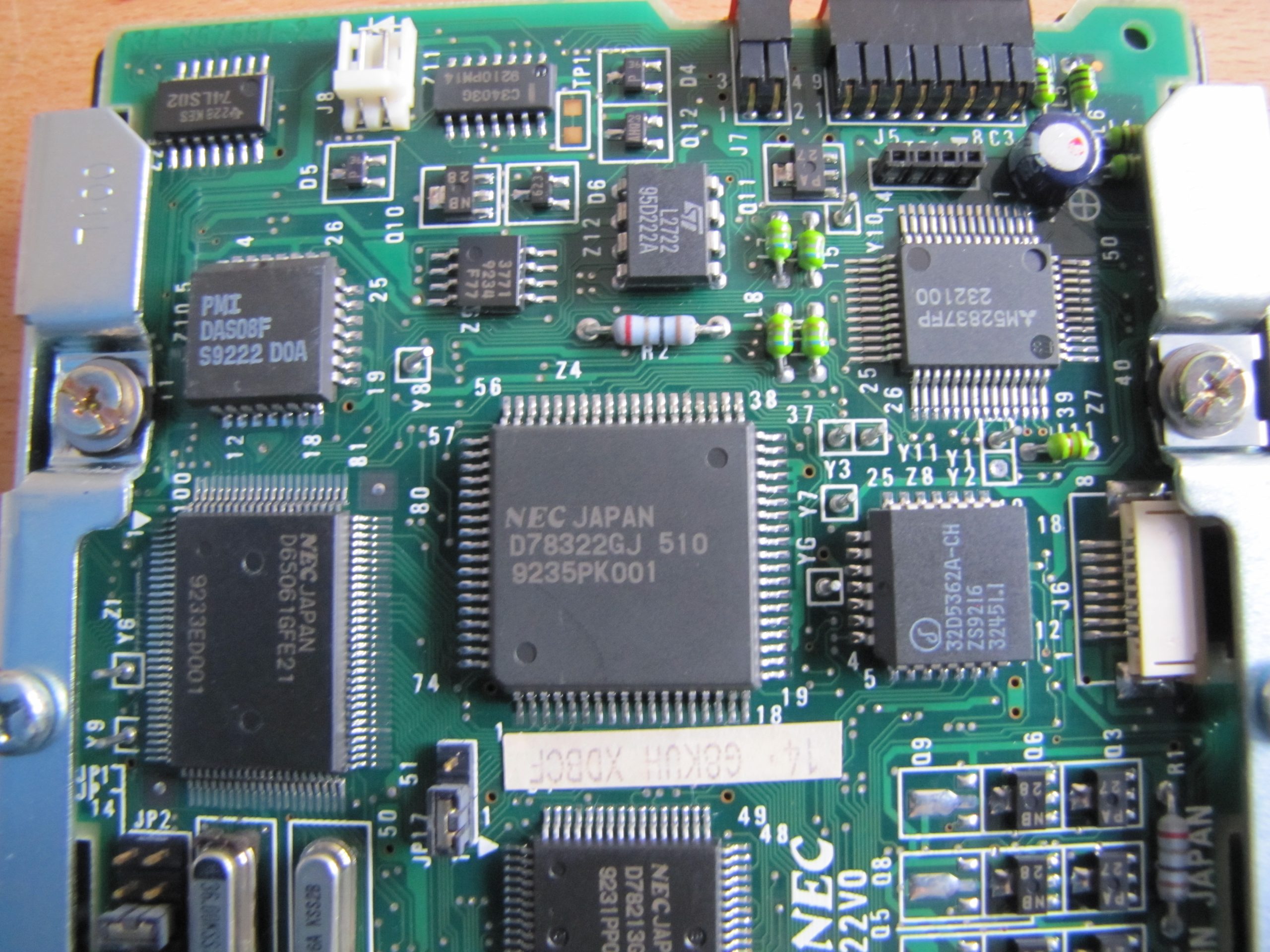

Interestingly, the main controller IC lacks any basic information. The usual small amount of buffer RAM is present too, being supplied by NEC themselves, as one would expect. NEC demonstrate in their future designs their ability to produce practically every IC required for hard drive logic control, much the same is shown here too.

The jumper settings for JP12 & JP13 are as follows:

JP12/JP13 Master/Slave Jumper Settings:

+----------------------------------------+--------+--------+

|Function | JP12 | JP13 |

+----------------------------------------+--------+--------+

x |Set one drive connection mode | OPEN | OPEN |

+----------------------------------------+--------+--------+

|No setting is allowed | OPEN | CLOSED |

+----------------------------------------+--------+--------+

|Set to two drives connection master mode| CLOSED | OPEN |

+----------------------------------------+--------+--------+

|Set to two drives connection slave mode | CLOSED | CLOSED |

+----------------------------------------+--------+--------+

Once again, a few NEC IC’s make their presence known. Headers J5 and J7 connect to the head-stack & pre-amp assembly, whereas J6 connects to the spindle motor, which will be shown later.

The external LED header, denoted as J8, has the following pinout:

J8 External LED

----------------

+------+ 1 : LED anode side

| 1 2 | 2 : LED cathode side

----+------+---- PCB

A reasonably bare board, covered in a multitude of surface mount components.

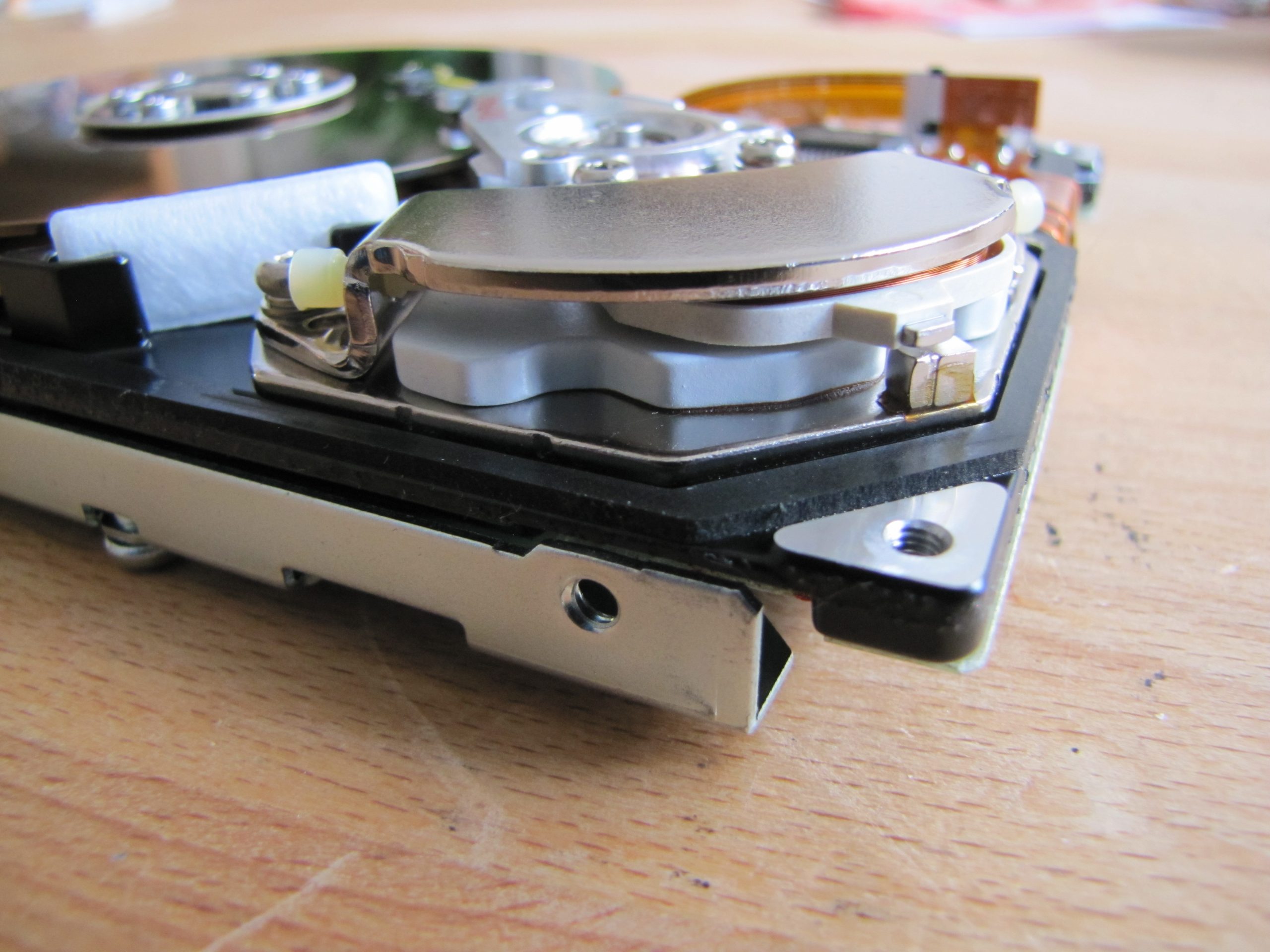

Accessing the underside of the drive, alongside the underside of the PCB as shown above, requires removal of these two mounting rails. It’s quite an interesting method compared to drives of the modern day, but it is very well built.

The underside of this drive is nice and clean, similar to the Toshiba MK-1034FC previously demonstrated in terms of sleekness. There’s nothing particularly interesting in terms of model numbers and the like, but there is one difference compared to later NEC D-series drives.

Clearly before the days of NEC’s preference to PM DM-T, they went with Nidec for this one. This particular motor doesn’t seem to hold up the best, seeing as most available audio recordings of D3756’s have horrifically poor bearings. Nonetheless, Nidec make good stuff.

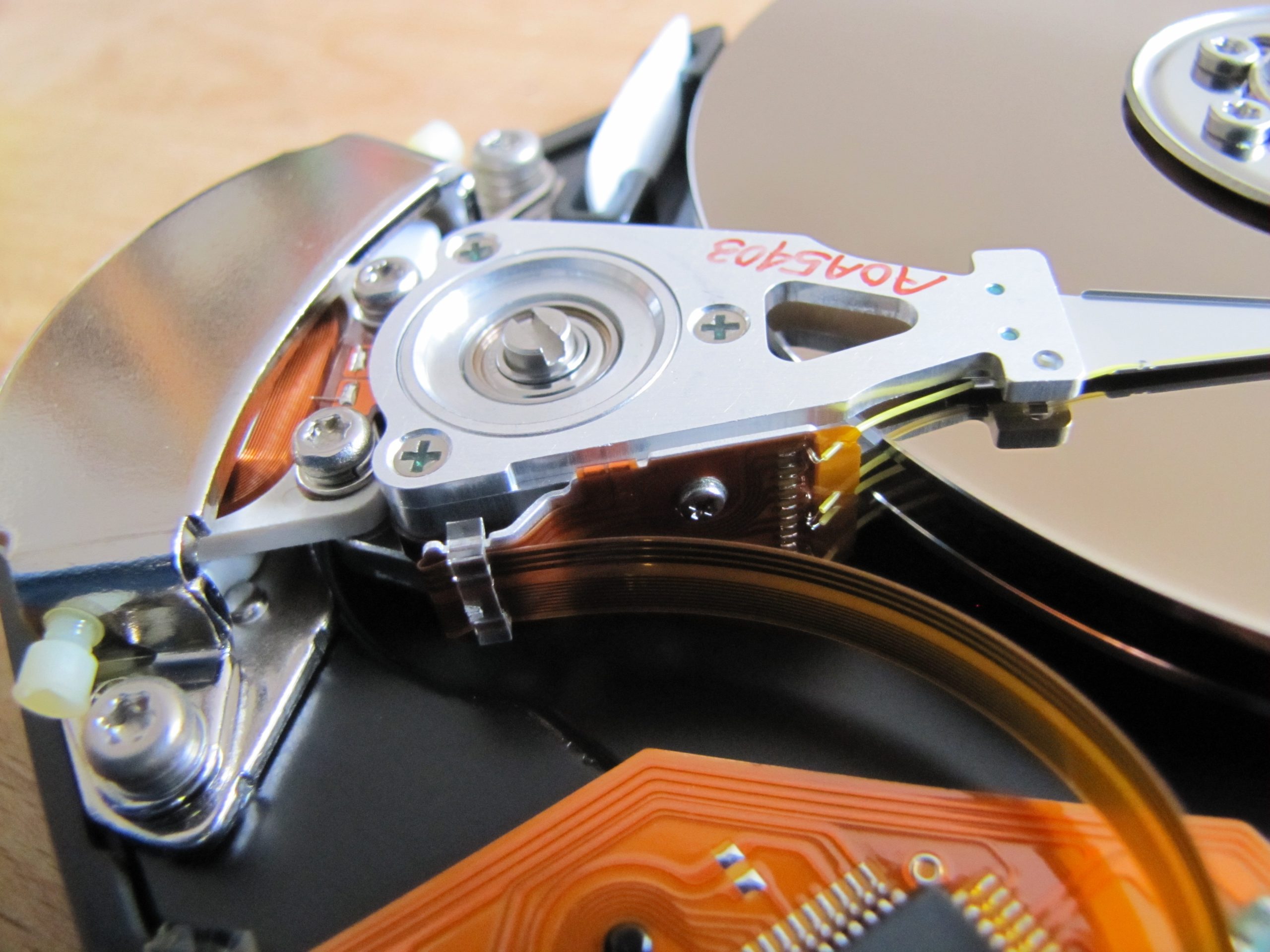

The internals of this drive clearly share some similarities to that of the much later D3766, but there are some major differences. Notably, the actuator arm design and breather-hole placement have been adjusted. It’s interesting to see.

An impressive piece of engineering, as is usual.

The preamp remains a component supplied by NEC, as remains the case in future models.

Fortunately, lacking the dreaded black rubber mess one might expect from some drive models, NEC drives of this era hold up incredibly well. The bumpers consist of a plastic-like composite, with no signs of degradation. If this drive remained operational, I’m sure mechanical failure would have been the first thing to go, compared to bumper failure.

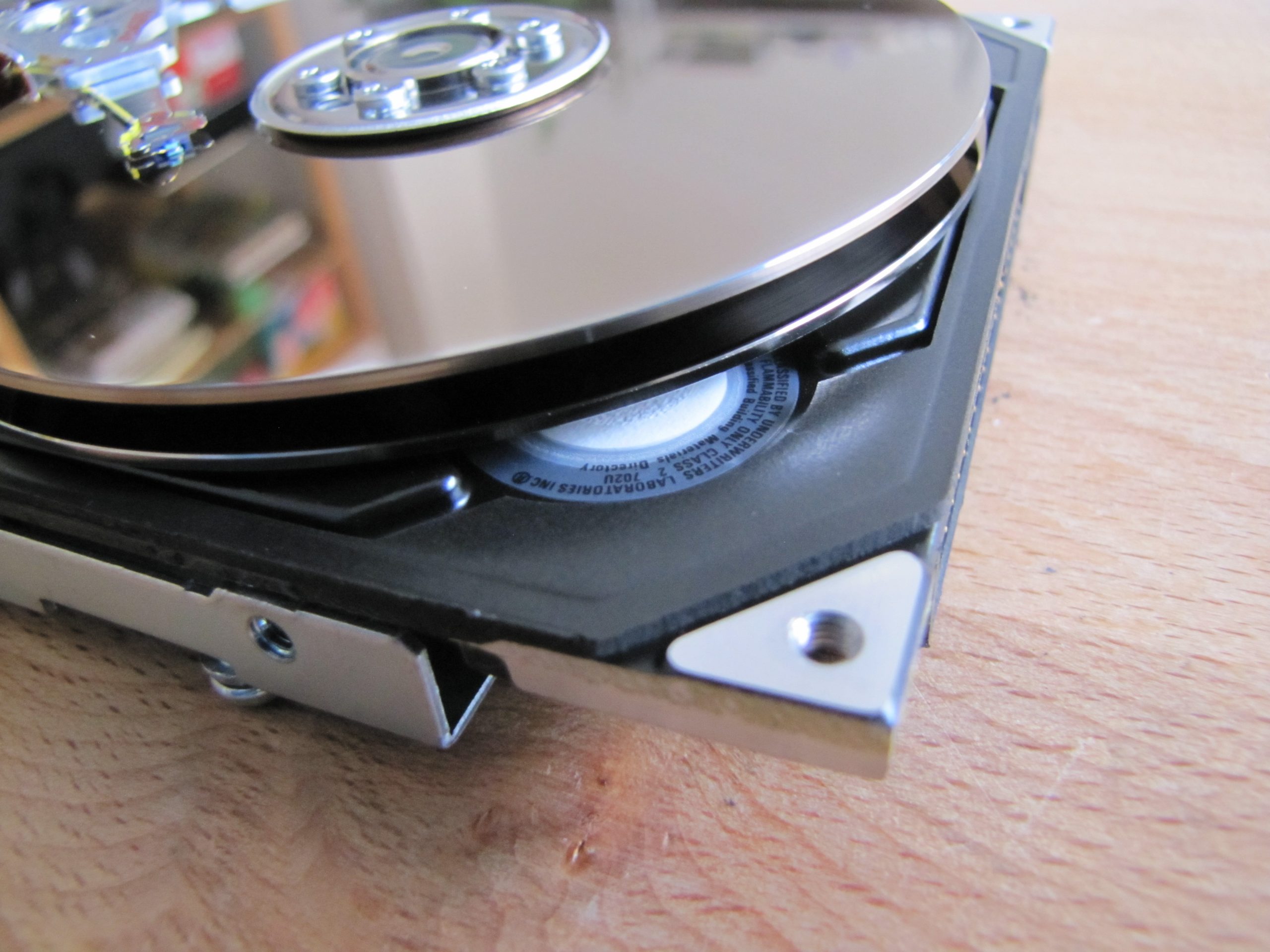

The air filter is in quite a strange place, not being visible from the get-go! It was supplied by Underwriters Laboratories, now known as UL Solutions.

Turning our attention to the top cover, NEC had their logo engraved once again. The design in general is quite impressive.

NEC obviously cared about humidity & moisture, placing a nice capsule of silica gel in the upper corner. It was supplied by Nippon Donaldson Ltd, which is still around today, continuing to provide filtration solutions.

While it’s a shame to see yet another NEC fall into failure, this one offered some interesting insights into NEC’s earlier hard drive operations. Generally, this model seems a little more robust compared to the likes of the D3711, but clearly they aren’t always winners.

If you’re curious as to how this one is in action, you can view my video on it running below: