The DiamondMax 11 series was announced in Q3 of 2005, available in both 400GB & 500GB capacities. A continued development of Maxtor’s long-existing designs, yet with a difference in label layout. While these were quite fast drives for the release year, this particular example doesn’t quite meet such expectations.

A failed unit is always a treat for one reason alone: we can look inside!

Drive Attributes -------------------------------------- Maxtor DiamondMax 11 6H400R0 -------------------------------------- Capacity 400GB Mfc Date 2006-01-21 Format 3.5" Interface PATA Platters 3 Heads 6 Cache 16MB RPM 7200 Origin Singapore (MSL) Codename Grizzly (PATA) --------------------------------------

Boasting three platters, alongside six heads, these drives offer a 133GB per-platter density. The 6H500R0/F0 was the highest end model, offering four platters instead to meet the 500GB expectation.

This unit was assembled in Singapore, by Maxtor Singapore Limited. This is far removed from MKE’s (Matsushita Kotobuki Electronics Co., Ltd.) production, which halted in 2004 alongside their industry departure.

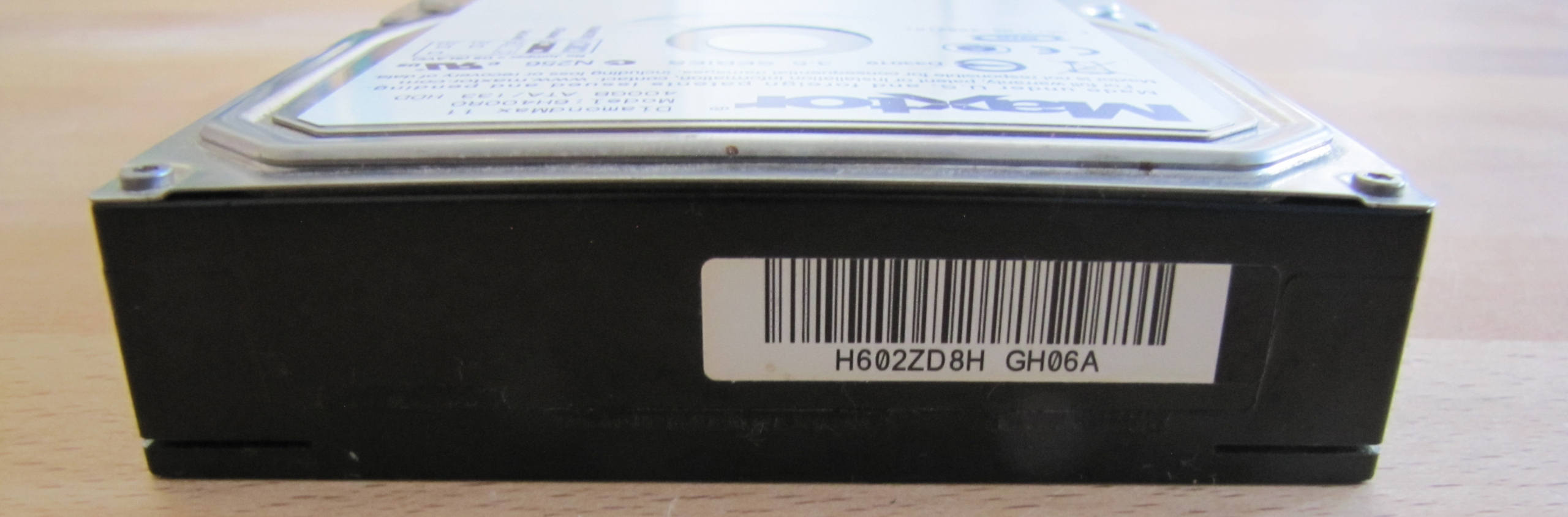

The label design is slightly different on these compared to models such as the DiamondMax 10, reaching across the entire top surface instead.

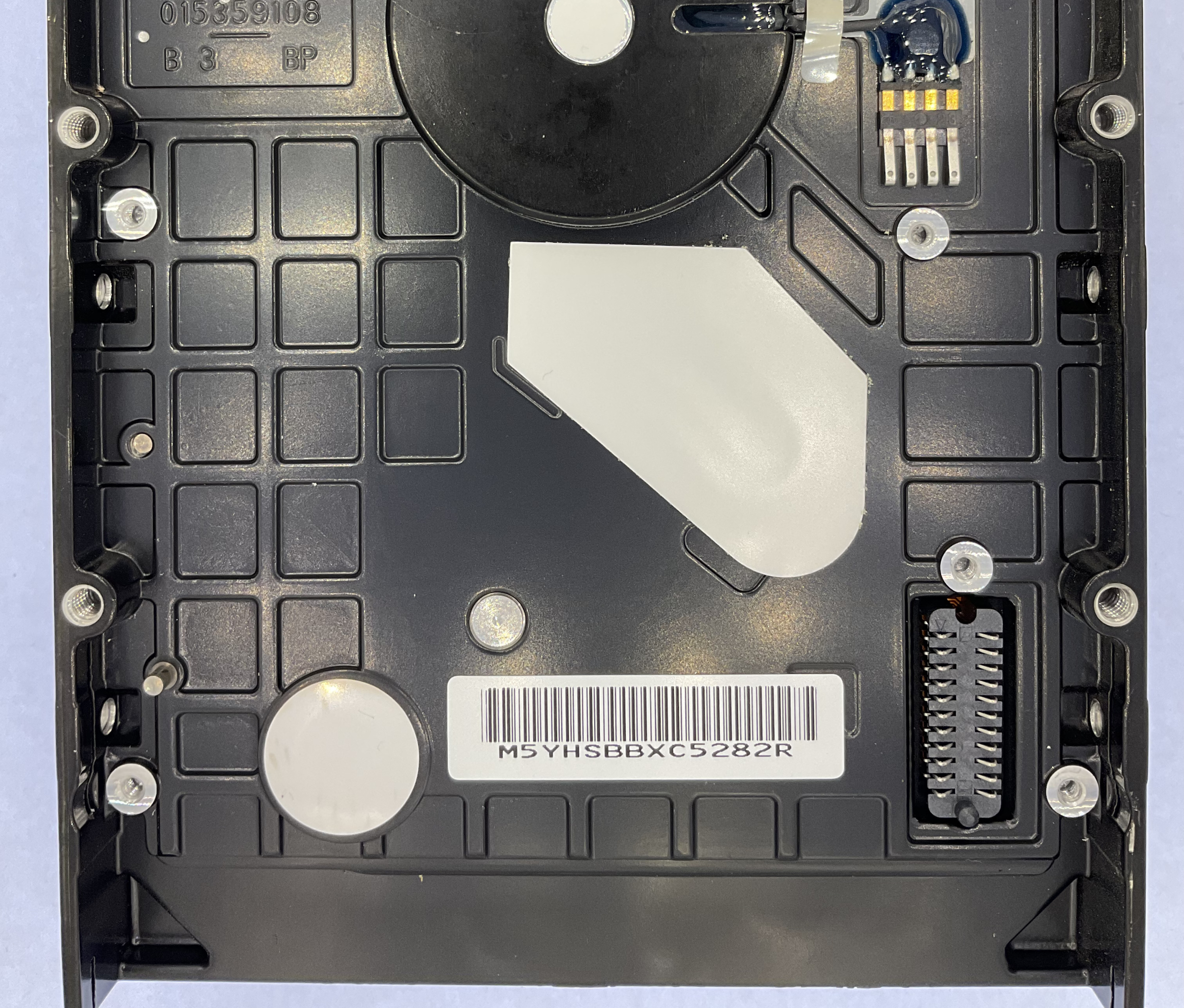

The usual Maxtor rear. The PCB is quite large, being rounded near the spindle motor cast. We’ll look at the PCB in more detail below.

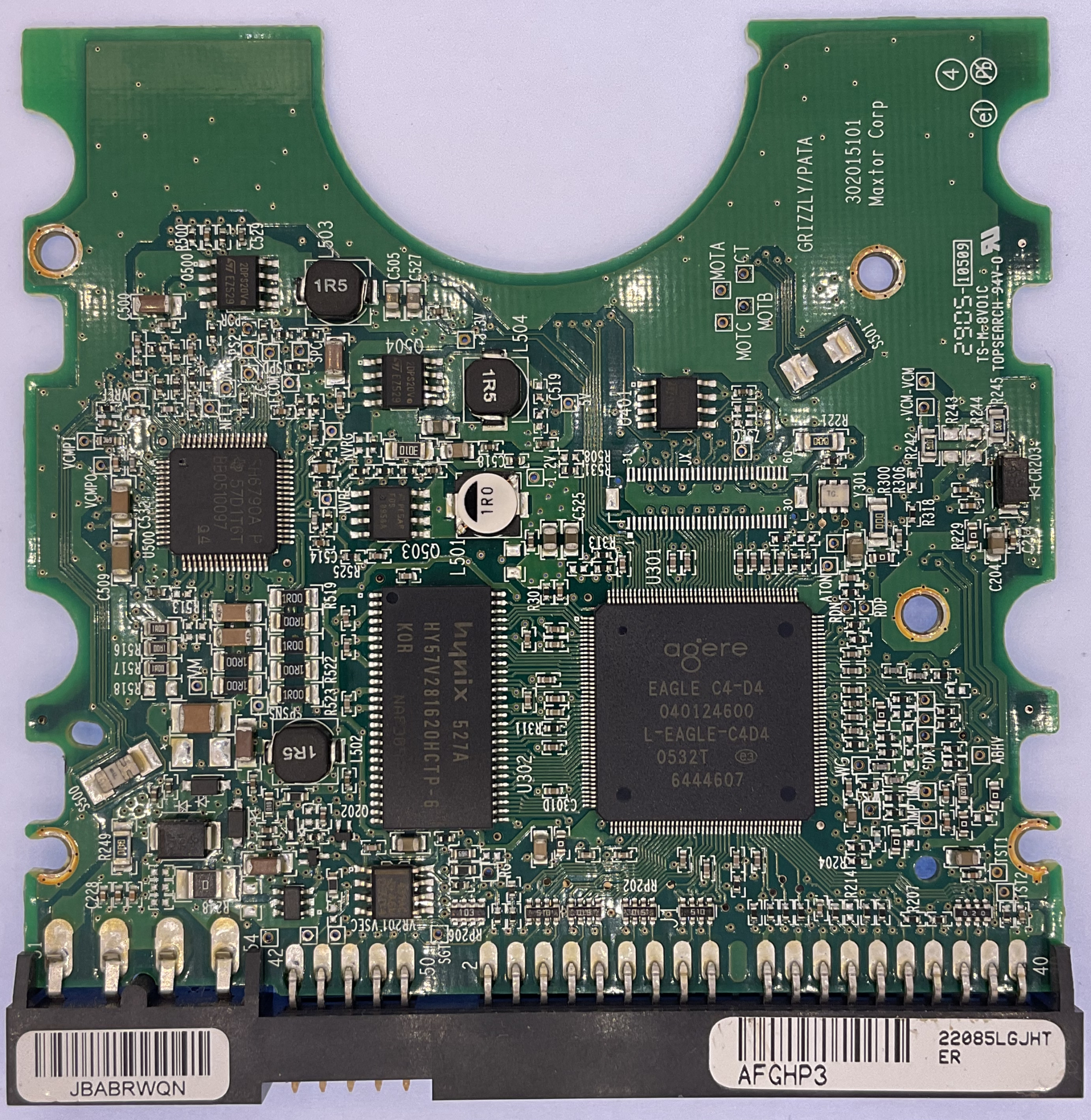

There’s three main logic IC’s. Agere provided the microcontroller, being part of their Eagle architecture. Hynix (now SK Hynix) provide 16MB of cache, with Texas Instruments supplying the spindle motor controller. Simple stuff.

The Grizzly/PATA architecture name Maxtor used for these is visible on the top right as silkscreen.

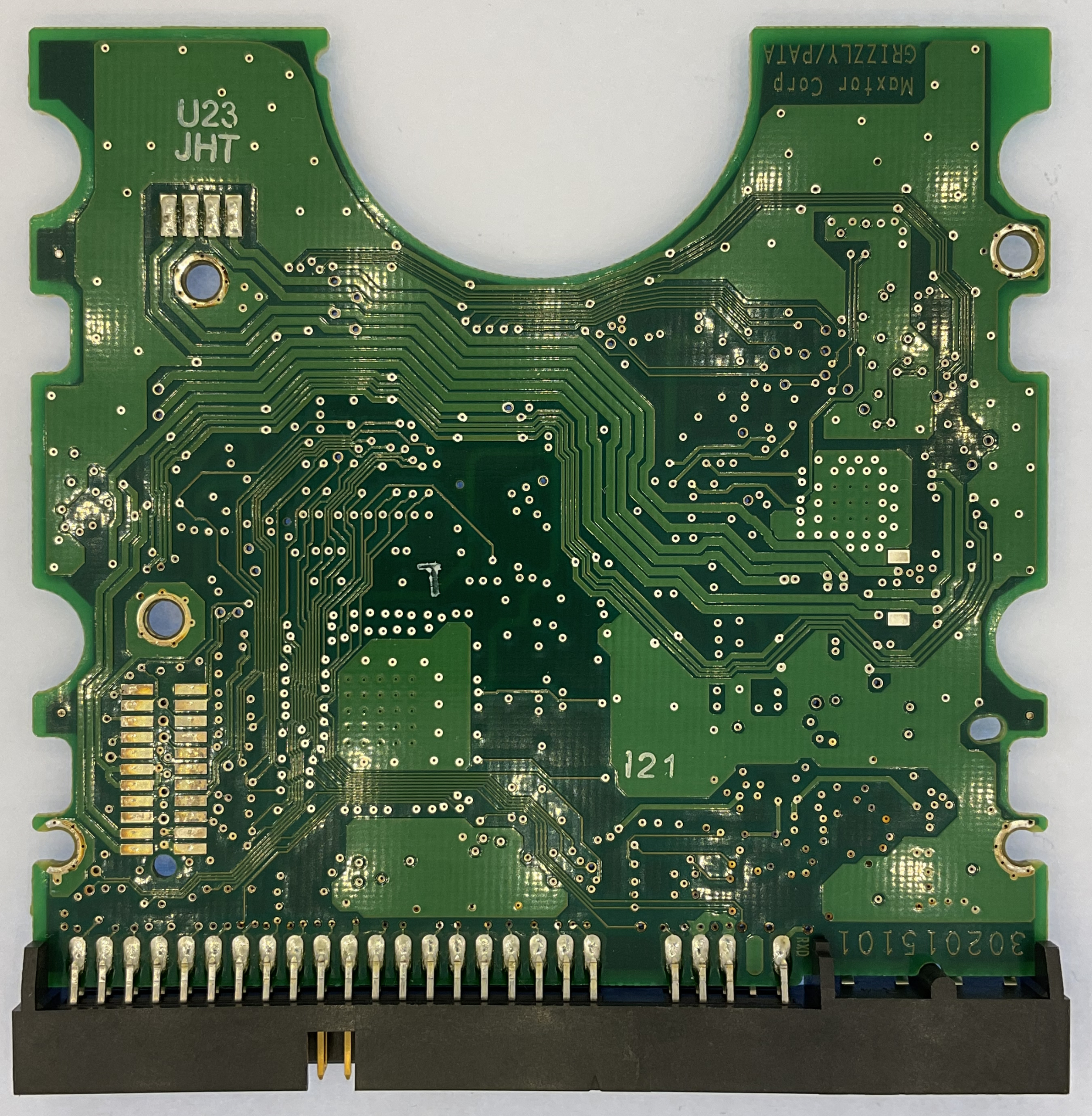

The backside of the PCB simply has contact pads for both the motor & head-stack assembly. The Grizzly/PATA codename is present once again.

All that meets us here is the head-stack pin connection array, alongside the four contact pins required for spindle-motor connection.

Under the foam & insulation layer, there’s a neat checkered imprint.

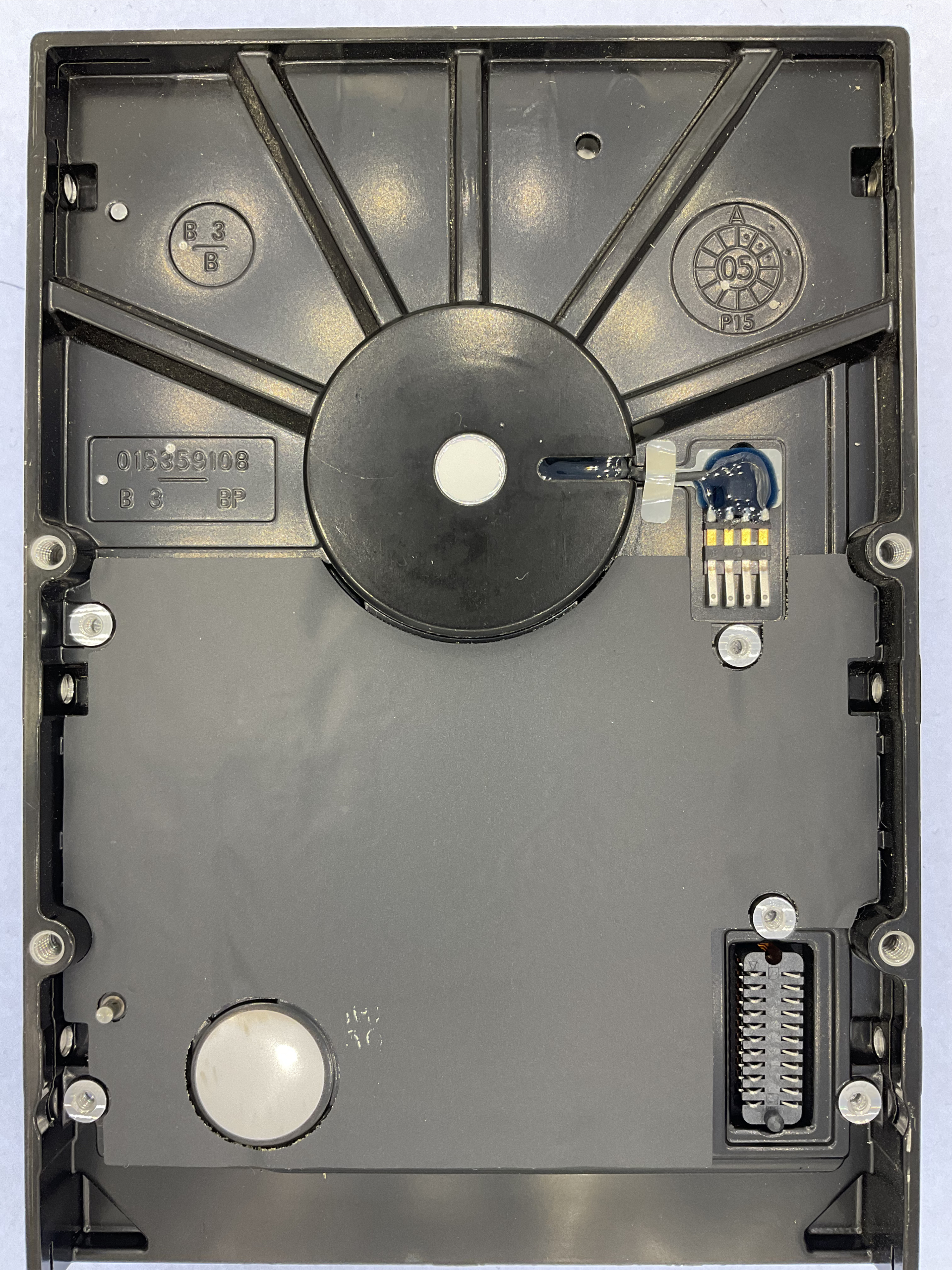

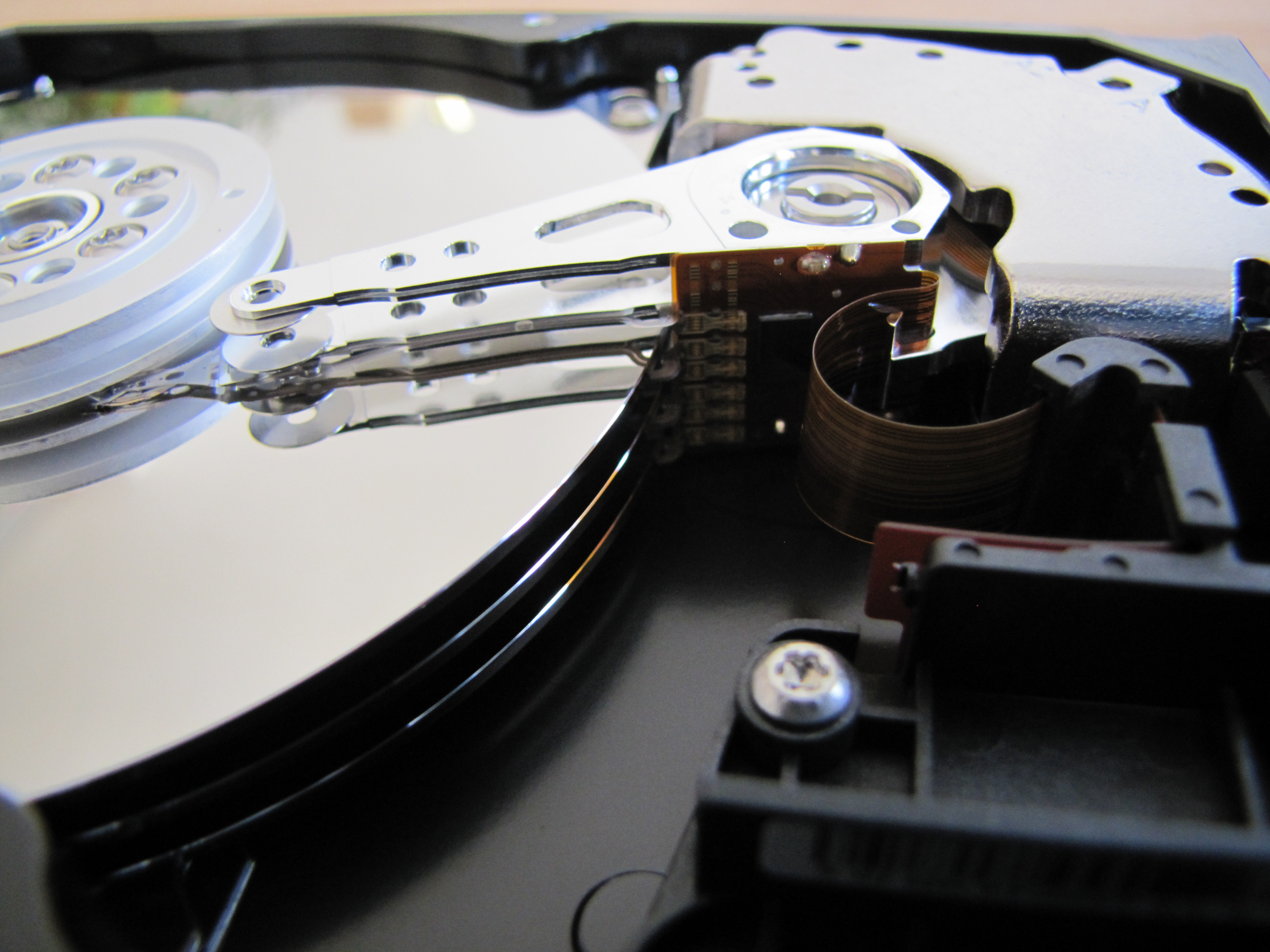

Internally, these are quite striking. Maxtor’s classic reversed actuator position design remains, alongside a fairly impressive spindle-motor hub.

Maxtor utilised a platter positioning cast for the spindle motor, fortunately retaining a capability for the heads to access the entire surface. The same cast was used for the higher end 6H500R0, with this 6H400R0 ensuring arm inertia remains the same with two blanked arm stilts.

From this angle, the preamp for the heads is just slightly visible.

Popping the top magnet off the actuator assembly reveals quite a nice bumper system. Fortunately, the main bumper stopper is shielded by a plastic assembly, so rubber degradation should be a fairly minute cause for future concern.

The underside of the top plate isn’t too interesting, but it’s still something to document.

For reference, this drive failed spontaneously during a surface scan. This drive was previously in perfect health, before deciding to depart from the world with little to speak of. No signs of failure were present beforehand. Either way, no models exist that haven’t suffered from spontaneous failure at least once, so luck can always be against those who play with old hard drives.

While this drive has suffered an unfateful end, looking inside one of the more modern Maxtor’s is always a treat.

Maxtor DiamondMax 11 Product Overview (.pdf)

If you missed the video I made on this drive, you can find it here: